PRODUCTS

Location:Home > PRODUCTS > Chemical accessories > Silicone Adhesive Glue > Adhesive

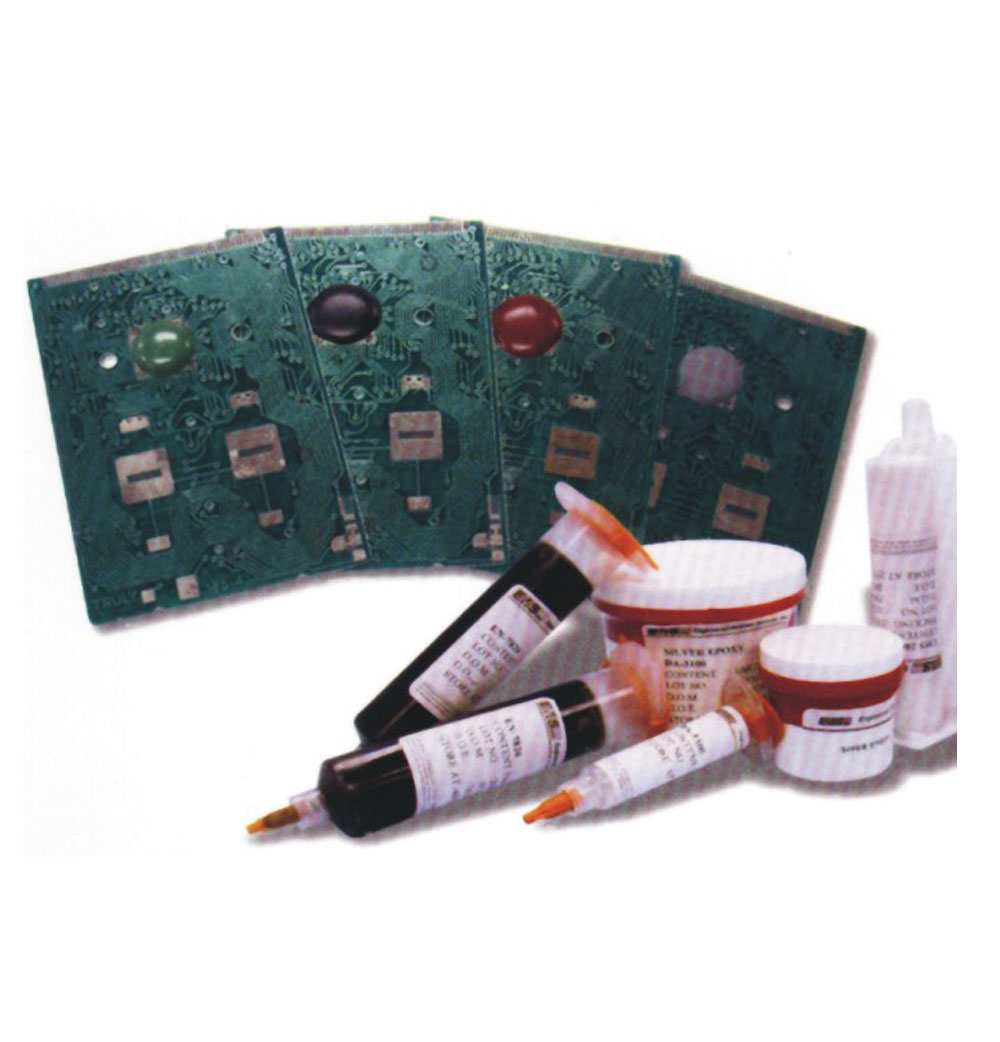

Adhesive

·It has excellent low-temperature storage stability (it can be stored for six months at 0 ℃).

·Good hardening effect can be achieved at appropriate temperature.

·The stable viscosity value at room temperature can reach a fixed amount of glue at any time according to different glue dropping equipment and air pressure, so that the special process requirements have good operability.

·After hardening, it can withstand the cold and heat shock of - 55 ℃ ~ 125 ℃ for hundreds of times, and the IC chip can still survive. It can be widely used to help fix the cover sealing process (COB) on the board of LCD liquid crystal display module (LCM) driving IC.

·Characteristics after hardening: all tests are carried out at 25 ℃.

·Unless otherwise specified, glass transition point (temperature resistance point) (TG) ℃: 140 ℃ minimum

·Extension rate: 1.8%

·Linear thermal expansion coefficient ppm / ℃: 35 (40-120 ℃)

·Tensile strength: 8000 PSI

·Thermal conductivity: 10 cal x.5 cm x.sec

·Density (GM / CC): 1.46