PRODUCTS

Location:Home > PRODUCTS > Heat Shrinkable Tubes Series > PE Environmental-Friendly Shrinkable Tubes > Heat-shrinkable tube135℃

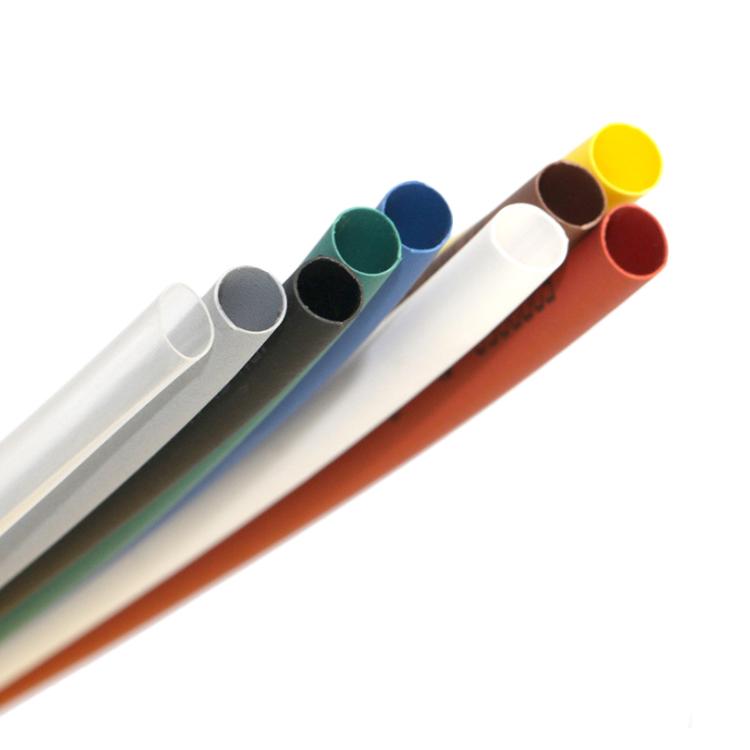

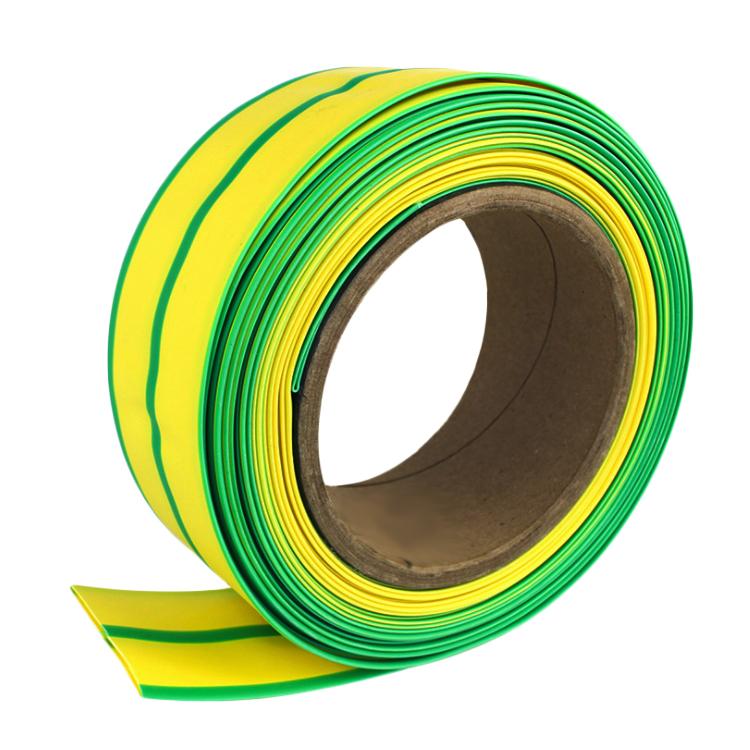

Heat-shrinkable tube135℃

Feature: use special formula and technology, capable of excellent anti-friction. Because of the outstanding performance in physics, chemistry and electricity, Application: Flame resistant liquid and solvent matches UL224 135℃ and AMS-DTL-23053/5 class 1 standard.

Standard lowest shrinking temperature: 120℃

Working temperature: -55℃to+135℃

Shrinking Proportion: 2:1

Performance | Test Method | Index | ||

Physics Characteristics | Tensile Strength ( MPa ) | GB/T1040 | ≥10.4 | |

Breaking Elongation (%) | GB/T1040 | ≥200 | ||

Tensile Strength after heat aging ( MPa ) | UL224 180 0 C×168hr | ≥7.30 | ||

Breaking Elongation after aging (%) | UL224 180 0 C×168hr | ≥100 | ||

Heat Resistance | UL224 280 0 C×4hr | Non-tacky, non cracking | ||

Cold bending Resistance | UL224 - 30 0 C×4hr | Non cracking | ||

Electrical Characteristics | Breakdown Strength ( kv/mm ) | GB/1410 | ≥25 | |

BreakdownVoltage | 150V | UL224 | 1500V Not Breakdown | |

600V | UL224 | 2500V NotBreakdown | ||

Ratio of Volume Resistance ( Ω·m ) | GB/1410 | ≥1×10 15 | ||

Chemical Characteristics | Corrosion Resistance | UL224 180 0 C×168hr | Non-corrosion | |

Copper Stability | UL224 180 0 C×168hr | Pass | ||

Flame Resistance | UL VW-1 | Pass | ||

Usual Specification

Specification ( mm ) | Before Shrink | After Shrunk |

Package (M/roll) | ||

Inner Diameter | Layer Average Thickness | Inner Diameter | Layer Average Thi | ||

Φ0.8 | 1.3±0.2 | 0.13±0.05 | 0.50 | 0.22±0.05 | 200 |

Φ1.0 | 1.5±0.3 | 0.18±0.05 | 0.65 | 0.28±0.05 | 200 |

Φ1.5 | 2.0±0.3 | 0.18±0.05 | 0.85 | 0.32±0.05 | 200 |

Φ2.0 | 2.5±0.3 | 0.18±0.05 | 1.00 | 0.35±0.05 | 200 |

Φ2.5 | 3.0±0.4 | 0.20±0.05 | 1.25 | 0.38±0.05 | 200 |

Φ3.0 | 3.5±0.4 | 0.20±0.05 | 1.50 | 0.40±0.05 | 200 |

Φ3.5 | 4.0±0.4 | 0.20±0.05 | 1.75 | 0.42±0.05 | 200 |

Φ4.0 | 4.5±0.4 | 0.23±0.05 | 2.00 | 0.45±0.05 | 200 |

Φ4.5 | 5.0±0.4 | 0.23±0.05 | 2.25 | 0.50±0.08 | 100 |

Φ5.0 | 5.5±0.4 | 0.23±0.05 | 2.50 | 0.55±0.08 | 100 |

Φ6.0 | 6.5±0.4 | 0.28±0.05 | 3.00 | 0.55±0.08 | 100 |

Φ7.0 | 7.5±0.4 | 0.28±0.05 | 3.50 | 0.55±0.08 | 100 |

Φ8.0 | 8.5±0.5 | 0.28±0.05 | 4.00 | 0.60±0.08 | 100 |

Φ9.0 | 9.5±0.5 | 0.30±0.08 | 4.50 | 0.60±0.08 | 100 |

Φ10 | 10.8±0.5 | 0.30±0.08 | 5.00 | 0.60±0.08 | 100 |

Φ11 | 11.5±0.5 | 0.30±0.08 | 5.50 | 0.60±0.08 | 100 |

Φ12 | 12.5±0.5 | 0.30±0.08 | 6.00 | 0.60±0.08 | 100 |

Φ13 | 13.5±0.5 | 0.33±0.10 | 6.50 | 0.65±0.08 | 100 |

Φ14 | 14.5±0.5 | 0.35±0.10 | 7.00 | 0.65±0.08 | 100 |

Φ15 | 15.5±0.6 | 0.38±0.12 | 7.50 | 0.70±0.08 | 100 |

Φ16 | 16.5±0.6 | 0.38±0.12 | 8.00 | 0.70±0.08 | 100 |

Φ17 | 17.5±0.6 | 0.38±0.12 | 8.50 | 0.70±0.08 | 100 |

Φ18 | 19.0±0.7 | 0.40±0.15 | 9.00 | 0.80±0.15 | 100 |

Φ20 | 21.5±0.7 | 0.40±0.15 | 10.00 | 0.80±0.15 | 100 |

Φ22 | 23.5±0.7 | 0.42±0.15 | 11.00 | 0.80±0.15 | 100 |

Φ25 | 25.6±0.7 | 0.45±0.15 | 12.50 | 0.90±0.15 | 50 |

Φ28 | 29.0±0.7 | 0.45±0.15 | 14.00 | 0.90±0.15 | 50 |

Φ30 | 31.5±0.7 | 0.45±0.15 | 15.00 | 0.95±0.15 | 50 |

Φ35 | 36.5±0.7 | 0.50±0.15 | 17.50 | 1.00±0.15 | 50 |

Φ40 | 41.5±0.7 | 0.50±0.15 | 20.00 | 1.00±0.15 | 50 |

Φ50 | 51.5±0.7 | 0.50±0.15 | 25.00 | 1.00±0.15 | 25 |